Improving Plant, Industries performance through Instrument Calibration & Continuous Monitoring

Credits : M Babb

Calibration helps a power plant to maintain and improve safety, as well as to meet national and international standards. However, calibration is also a matter of profitability. By using high-accuracy calibration equipment, the accuracy of vital measurements can be maintained at required levels and plants can increase their annual power production capability.

Instrumentation is used to measure energy flow within power and energy operations in order to monitor and improve operations.

While these instruments are not directly used for billing purposes, their proper operation is often key to identifying and preventing energy losses that can have large economic consequences.Failure to properly calibrate these instruments can leas to significant economic consequences.

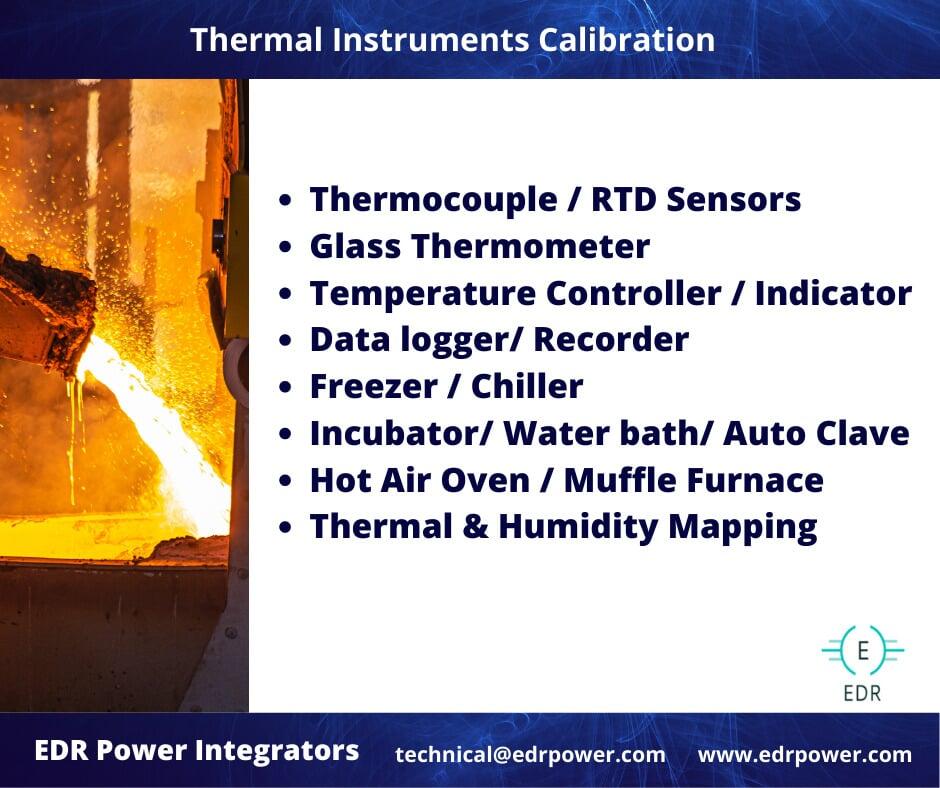

Instruments typically calibrated in power plants include transmitters, switches, gauges, transducers, frequency devices and pulse counters. Failure to properly in a timely manner is an important aspect of ensuring the environment integrity of the process that can reduce the number and severity of environmental issues.

Increasing productivity and safety

Accurate measurements can allow increased energy production. For instance, reducing the measurements uncertainty in a power plant can potentially increase electrical production to nearly 2 % .